Copper Hot Line Clamp

Copper Hot Line Clamp are live line instruments that can be used to connect distribution taps.Castings made of bronze and aluminum alloys are very strong, resistant to corrosion, and compatible with conductors.

Excellent conductor contact, lower joint temperature, less conductor cold flow, and less conductor twisting during installation are all benefits of an extended jaw width.

The spring-loaded feature reduces vibrations caused by tightening torque and accounts for cold flow.

Forged eye bolts offer uniform expansion under load and strength without corrosion. The tap connection on the side guards against potential conductor or clamp-on bimetal connection corrosion. According to ANSI C119.4, successful Current Cycle testing guarantees that the MPS hot line clamp can sustain the ampacity of a correctly installed connection.

Suspension clamps, tension clamps, link fittings, splicing fittings, protective fittings, guy wire fittings, and other electrical fittings with a variety of types and specifications for high and low voltage power transmission and substation are the primary products of Kaizen Metals India.

Any aluminum or aluminum-covered conductor can be used with hot line clamps made of high conductivity aluminum alloy. Vibration-resistant connections are made possible by an enclosed compression spring on the clamp run's eye screw thread.

Features Copper Hot Line Clamp

Application:

- Hot line tap clamp is used for non-load-bearing connections and branches of conductors in overhead power lines.

Features:

- 1.Hot line tap clamp can carry out live operation on wire connector and grounding rings, with simple structure and convenient operation.

- 2.Hot line tap clamp can be effectively applied to the live work of the line, reducing the base of power outages, avoiding large-scale power outages, and maintaining the reliable operation of the power grid.

Installation:

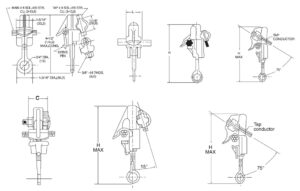

- 1- Adjust the opening to the maximum by turning the screw

- 2- Once the branch wire is processed, clip one end into the opening and secure

- 3- Use the fire control lever and other tools to align the opening of the branch clamp with the main wire, and rotate the operating rod to drive the opening screw to rotate; make it fasten to the main wire

Technical Details:

| Models | LLC1520 | E1030-AC | LLC1530 |

| Main Line(mm²) | 16-70 | 10-120 | 16-185 |

| Service Line(mm²) | 16-50 | 10-70 | 16-95 |

| Main Line(AWG) | 6 sol-2/0 str al | 8 sol-4/0 str al | 6 sol-400MCM al |

| Service Line(AWG) | 6 sol-1/0 str sl/cu | 8 sol-2/0 str al/cu | 6 sol-2/0 al/cu |

| Bolt No. | 1 | 1 | 1 |

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client's requirements.

We can manufacture and export Copper Earth Rods as per specifications (custom drawing and samples) for more information, please